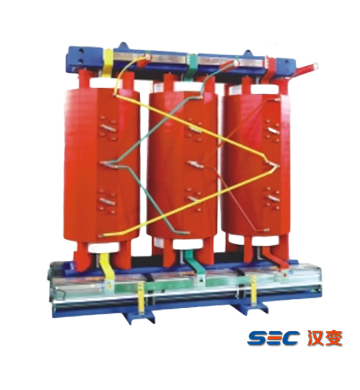

Product Introduction:

Rectifier

transformer is the power transformer of rectifier equipment. The characteristic

of rectifier equipment is that the primary side inputs alternating current, and

the secondary side outputs direct current after passing through rectifier

elements. Converter is the general term for the three operating modes of rectification, countercurrent, and frequency conversion, among which rectification

is the most widely used. A transformer used as a power source for rectification

equipment is called a rectifier transformer. Most industrial rectifier power

supplies are realized by the AC power grid through rectifier transformers and

rectifier equipment.

Product Features:

1.Superior harmonic interference resistance: Effectively reduce the pollution of high-order harmonic components on the power grid on the valve side, while also avoiding the interference caused by harmonic transmission from the grid side to the control system on the valve side.

2.Excellent mechanical performance: Optimized structural design, improved leakage magnetic distribution, reduced axial mechanical stress, and adopted unique processes to improve the mechanical stability of the transformer.

3.Stable equipment temperature rise: With years of design and manufacturing experience and scientific and reasonable design, the transformer efficiency has not only been improved, but also avoid the stray loss concentration caused by the oil hot spot temperature rise, so as to effectively prevent local overheating .to a certain extent, the operating life of the equipment is increased.

Contact us

Contact us